CSF is the largest and most popular manufacturer for A9X Supra & BMW B58 cooling systems. With enthusiasts, tuners, and race teams pushing these cars further than anyone ever anticipated, the time has come to complete the full cooling suite. CSF is pleased to announce the new High-Performance All-Aluminum Radiator for the A9X Supra.

Vehicle Fitment:

2020+ Toyota GR Supra L4-2.0L Turbo (A90 A91 MKV MK5)

2019+ BMW Z4 L4-2.0L Turbo

2019+ BMW G2X 330i & 330e (incl. xDrive)

Features:

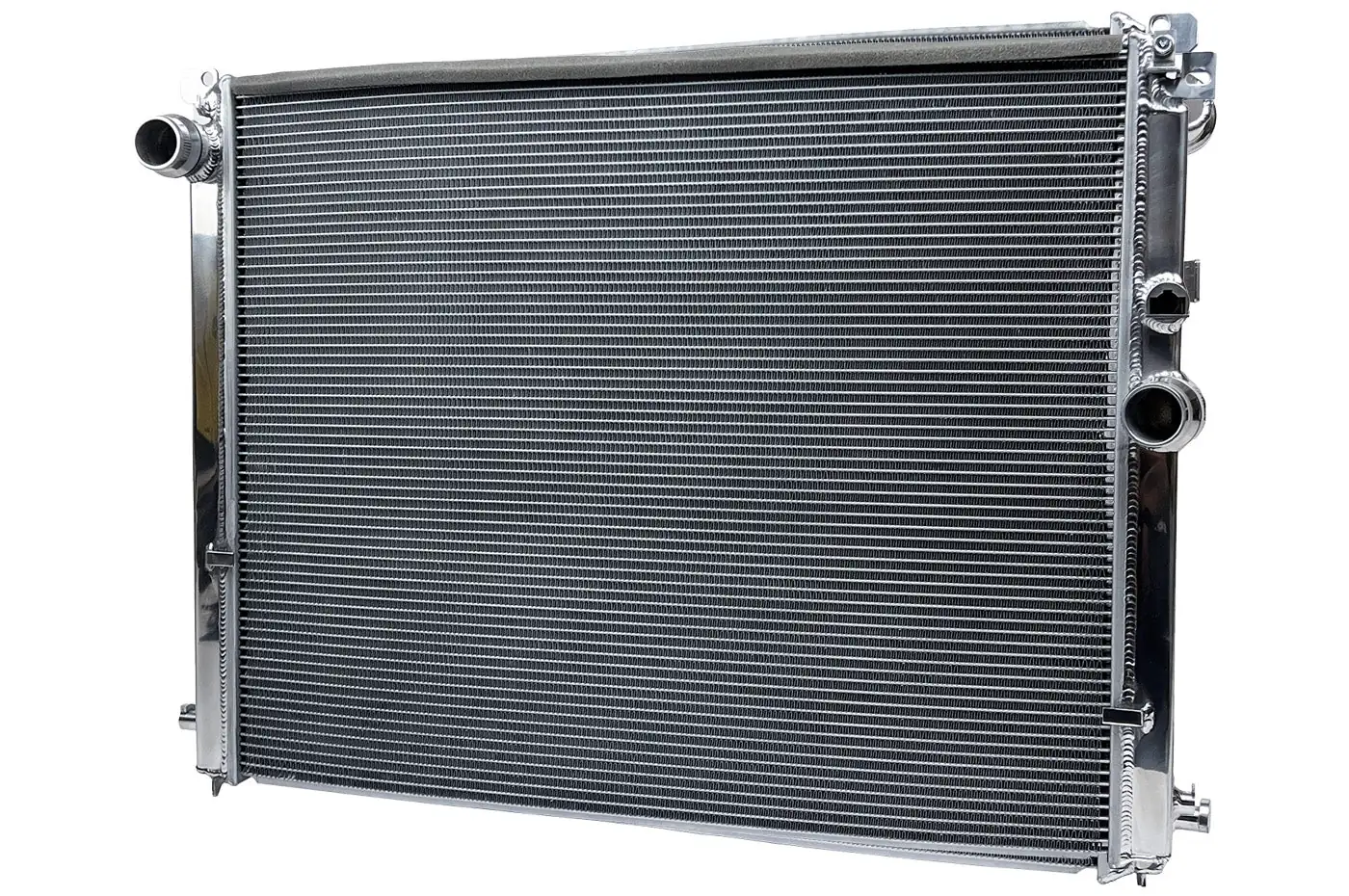

• 2-Row, 42mm Ultra-High-Performance Core

• Cooling Tubes with CSF’s Exclusive B-Tube Technology

• New 5mm Tall Ultra Efficient Fins with a Multi-Louvered Design for Maximum Surface Area Contact

• CNC Machined Mounting Brackets and OEM Style Inlet/Outlet

• 100% All Aluminum TIG-Welded Construction

• 1-Hour “Mirror Finish” Hand Polish

• True Plug-and-Play “Drop-in Fit” Installation Requires Absolutely No Modifications

• Individually Leak and Pressure Tested

• 2-Year Limited Warranty

• Toyota OEM Part Number: 16400-WAA01

• BMW OEM Part Number: 17118666739

More Info:

CSF is well known for making the best A9X Supra and BMW G-Series cooling systems on the market. Naturally, they have been most successful with the B58 crowd. With years of feedback from Customers, Race Teams, and Development Partners, CSF has more B58 cooling experience than any other company in the world.

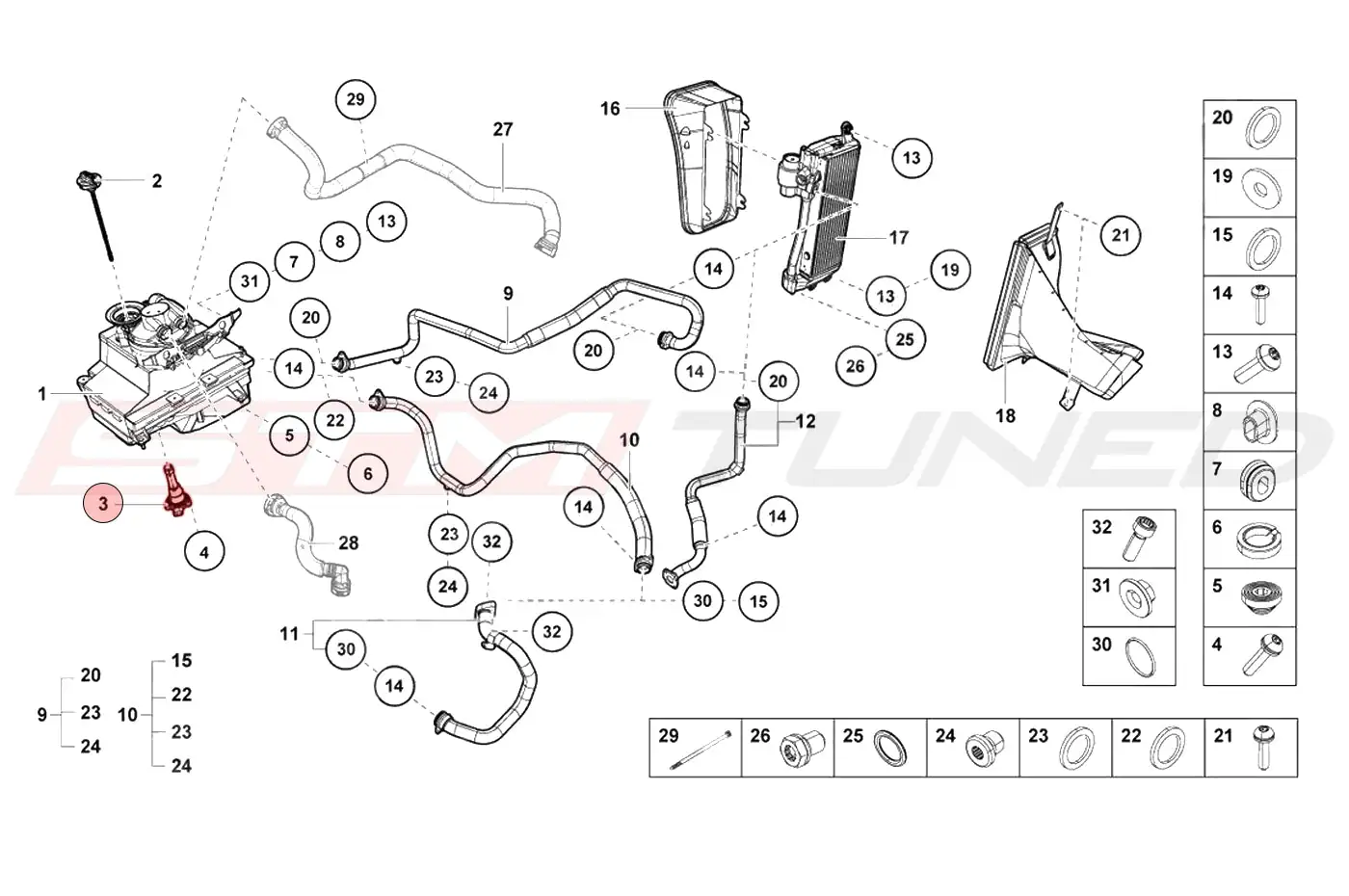

With more and more people pushing the limits of the Supra, the factory radiator has started showing its limitations. Bigger turbos cranking out more power create a lot more heat that needs to be dissipated. Furthermore, the heat exchanger is mounted directly in front of the radiator, so all the heat shed by the charge air system runs over it. In racing applications this can be detrimental to engine coolant temperatures and risk sending your Supra into limp mode. In addition, many of these cars are getting to an age where wear and tear necessitates replacement.

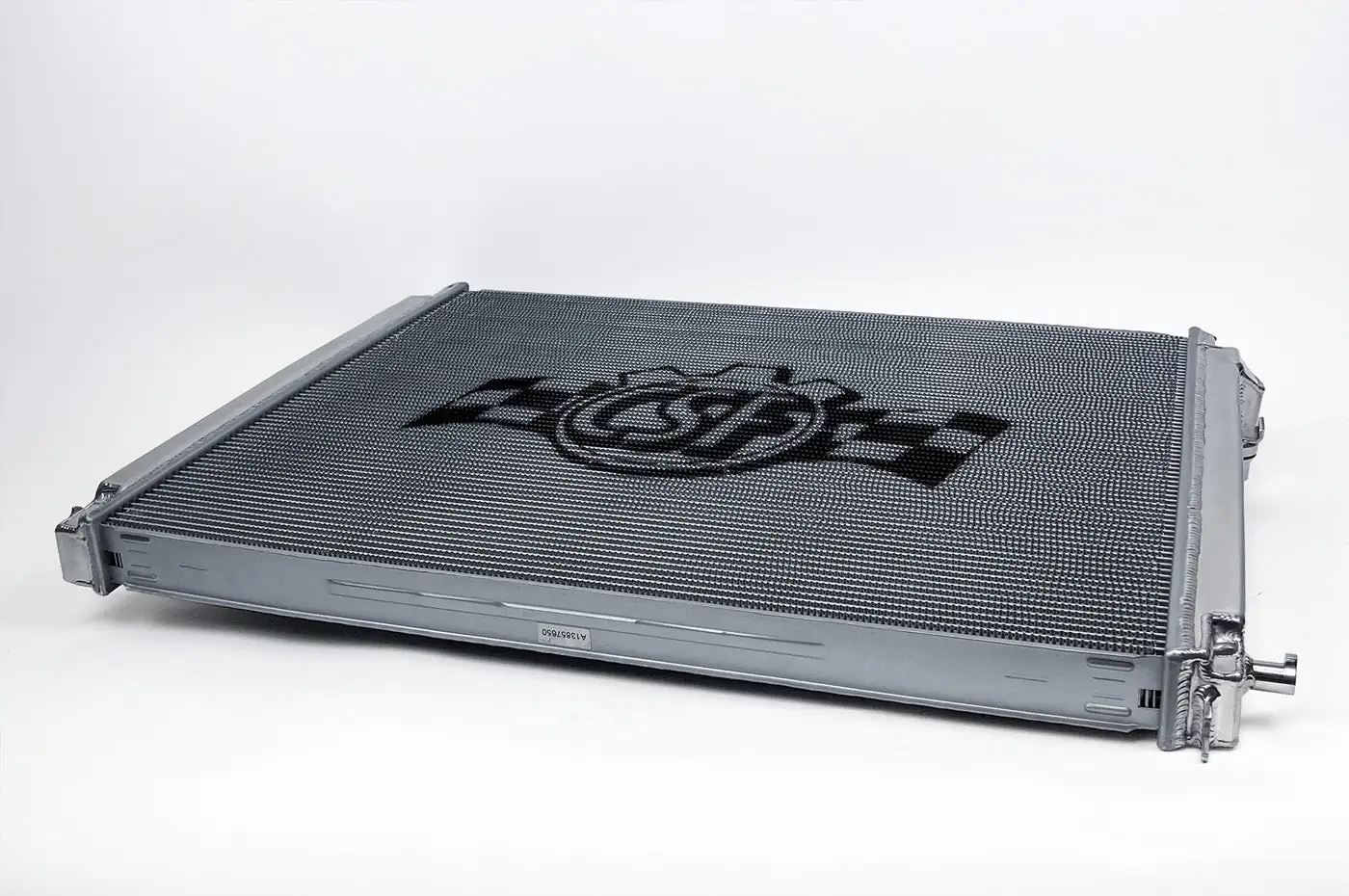

CSF began development of the Supra radiator over 1 year ago with thorough race testing done by Titan Motorsports and Studio RSR. To give customers the best possible performance, CSF incorporated its latest 5mm fin cooling technology. This new fin technology increases the heat transfer area over a traditional radiator by 20-25%.

CSF VS OEM:

The original OE radiator from Toyota/BMW is a plastic tank with a single row aluminum core design. While this is generally accepted as good quality and durable, there is always room for improvement. The 4mm fins on the OE radiator made the system fairly efficient for a factory unit. The core itself is one of the biggest limiting factors at only 34mm thick and a single cooling row.

With data collected by development partners and race teams, CSF was able to design the ideal High-Performance replacement. The CSF radiator features the latest 5mm fin technology. These fins significantly increase the heat exchange surface area improving overall cooling efficiency and recovery while still maintaining good airflow. The core is much larger than the factory featuring 2-Row 42mm aluminum core. This both increases the fluid capacity of the radiator, and improves the cores ability to dissipate heat. CSF’s Exclusive B-Tube Technology increases the heat transfer by approximately 15% over regular oval welded tubes. In addition, the super-efficient multi-louvered fins maximize airflow through the core for the best possible performance.

The TIG-Welded 100% All Aluminum construction increases the overall strength of the radiator. This improves durability and longevity so you can be confident it will hold up to hard driving conditions. The CSF radiator mounts in the factory location and requires no modifications or cutting.

| Feature: | CSF: | OEM: |

| # Core Rows | 2 | 1 |

| # Cooling Tubes | 69 | 81 |

| # Cooling Fin Rows | 70 | 82 |

| Fin Height | 5mm | 4mm |

| Core Thickness | 42mm | 34mm |

| Core Material | Aluminum | Aluminum |

| Tank Material | Aluminum | Plastic |

| Construction | 100% TIG Welded | Crimp on Gasket |

Real World Testing:

CSF understands that this radiator will be used in motorsport competitions. While it would have been easy to engineer a good radiator and call it a day, CSF wanted to make the best possible radiator that would hold up under the most demanding conditions. This requires more development time with a lot more testing, but the result is the ultimate performance radiator you can depend on. CSF worked closely with two R&D Partners to test the radiators in multiple motorsport environments. These initial test units were made using CSF’s 42mm 2-Row core with 6.5mm fins.

Drag & Roll Racing

Titan Motorsports was the perfect partner to test the radiator for drag racing applications. CSF has a long relationship with the team at Titan Motorsports. They have one of the fastest A90 Supras in the world and compete in drag and roll racing competitions across the US. Over the past year, the Supra has been run in countless competitions in some of the hottest and harshest environmental conditions. Over the past year, the radiator has performed very well offering lower engine temps at both idle and during runs.

Road Racing – Time Attack, Hill Climb, and More

For road racing applications, CSF worked closely with long-time R&D Partner Studio RSR. Their “Project Silver Speed” A90 Supra is a true road race vehicle that competes in a wide variety of events. Studio RSR ran the CSF prototype radiator through the complete season of Global Time Attack. They also ran the car at the 101st Pikes Peak International Hill Climb. Throughout their testing they saw lower maximum engine coolant temperatures as well as faster recovery times.

5mm Core Upgrade

While the 6.5mm fin version performed extremely well in testing, CSF always seeks to offer the ultimate cooling solution. Before going into final production the design was updated to incorporate CSF’s latest 5mm fin technology which was introduced at the end of 2023. This new core specification offers even more heat transfer area and thermal efficiency than the tested prototypes. CSF is confident this radiator is ready to take on the most demanding racing conditions in the world.